Melso Automation,

While it focuses on Water Processing in areas such as Industrial and Domestic Wastewater Treatment Facilities Automation, Pump Stations, Drinking Water Treatment Facilities Automation, it also offers solutions in the Food, Wood, Iron and Steel and Cement Sectors.

System Design - Bidding

At the initial stage of the projects, it evaluates your requests for proposals and, if deemed necessary, carries out feasibility studies in the field.

Technical Specification, P&ID, Equipment and Instrument list etc. In line with your technical data, it analyzes all the needs of your project and offers different, high-efficiency, most economical, optimum cost and effective solutions for each process.

System Design Configuration:

In the design phase of the projects, with its expert technical team with thirty years of experience in Process Automation and control, it offers the most suitable solution for your project by using the automation platforms of leading brands such as Siemens, Schneider, Abb, Rockwell. By taking the Process and Customer demands into consideration, it makes decisions on one of these platforms and determines the most appropriate System Configuration

.jpg)

.jpg)

Siemens Simatic S7 300/400-1200-1500 PLC, WinCC SCADA, Simatic HMI Panels are our first priority.

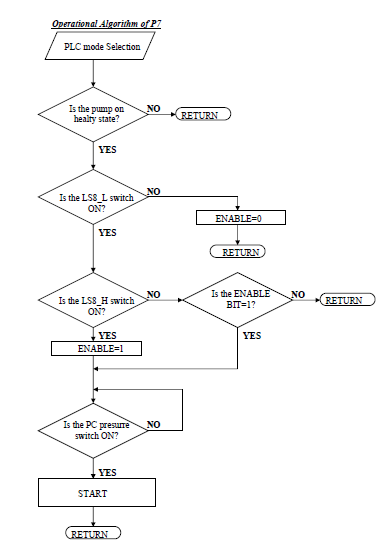

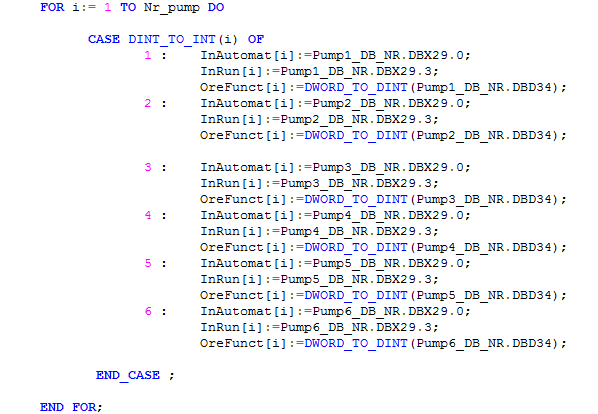

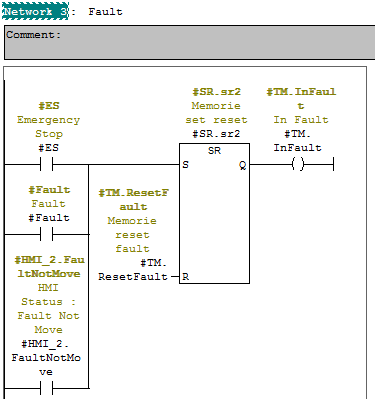

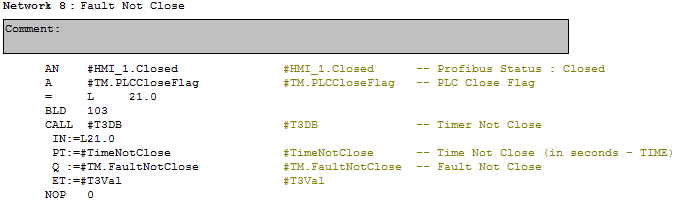

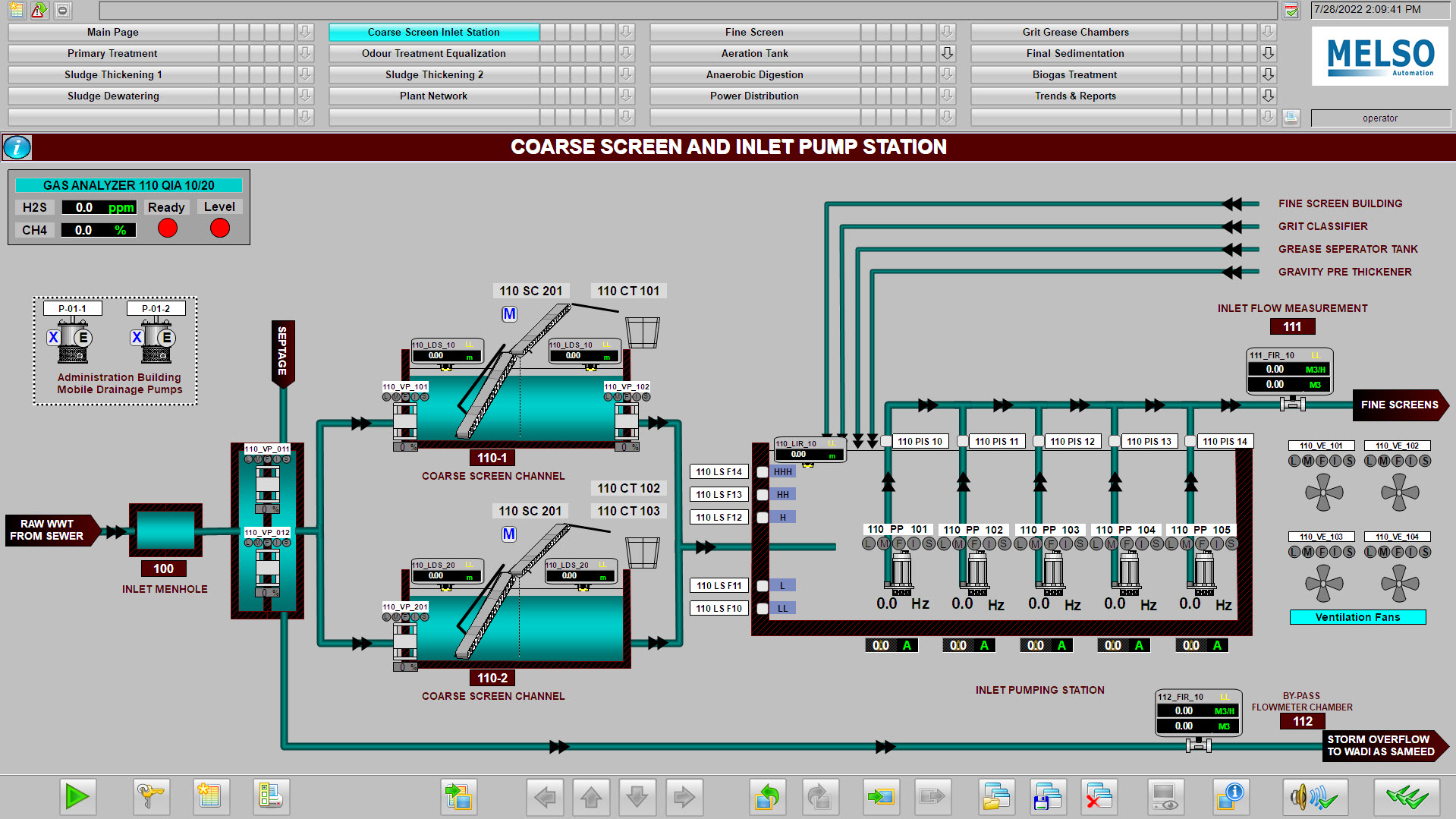

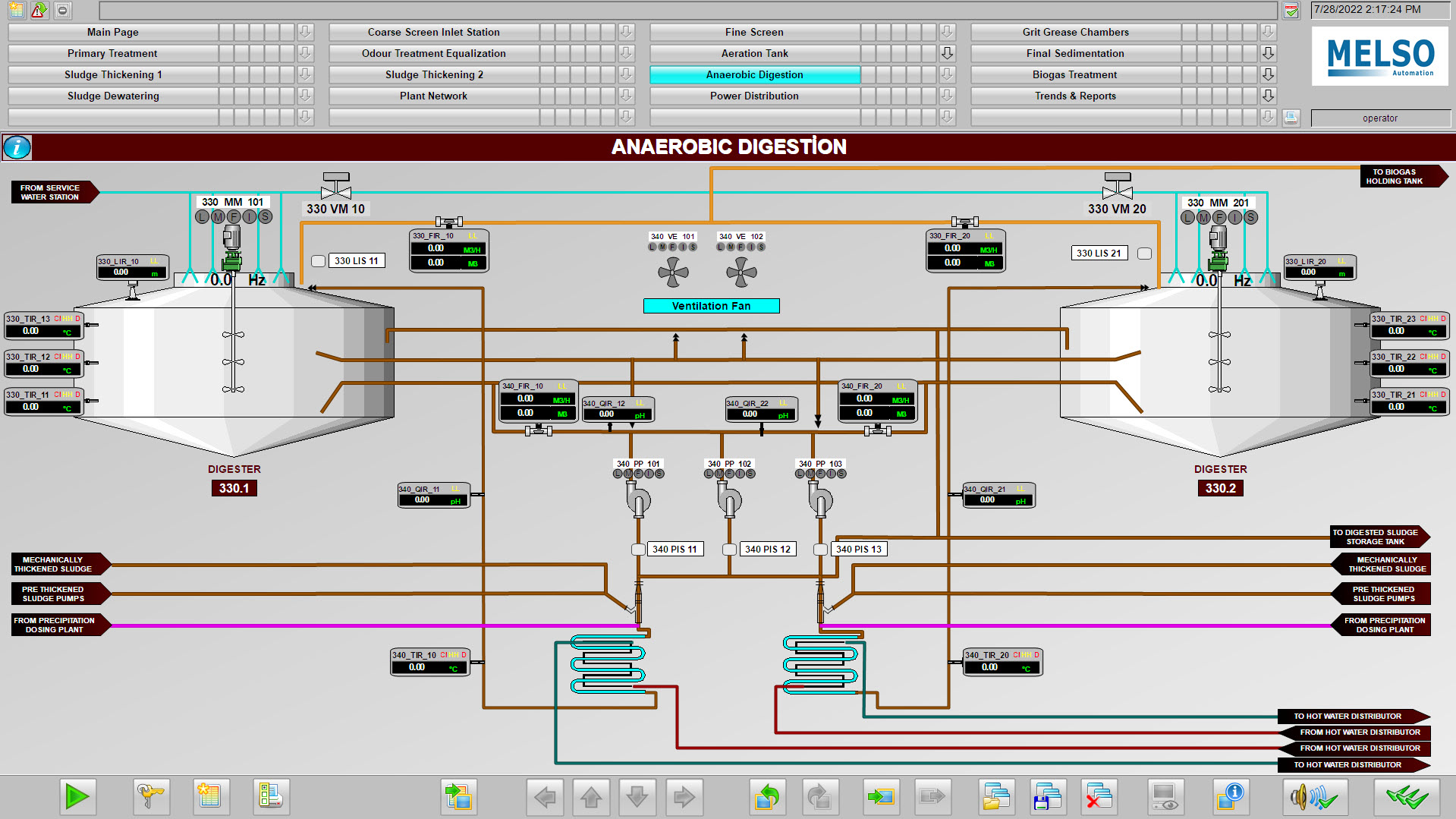

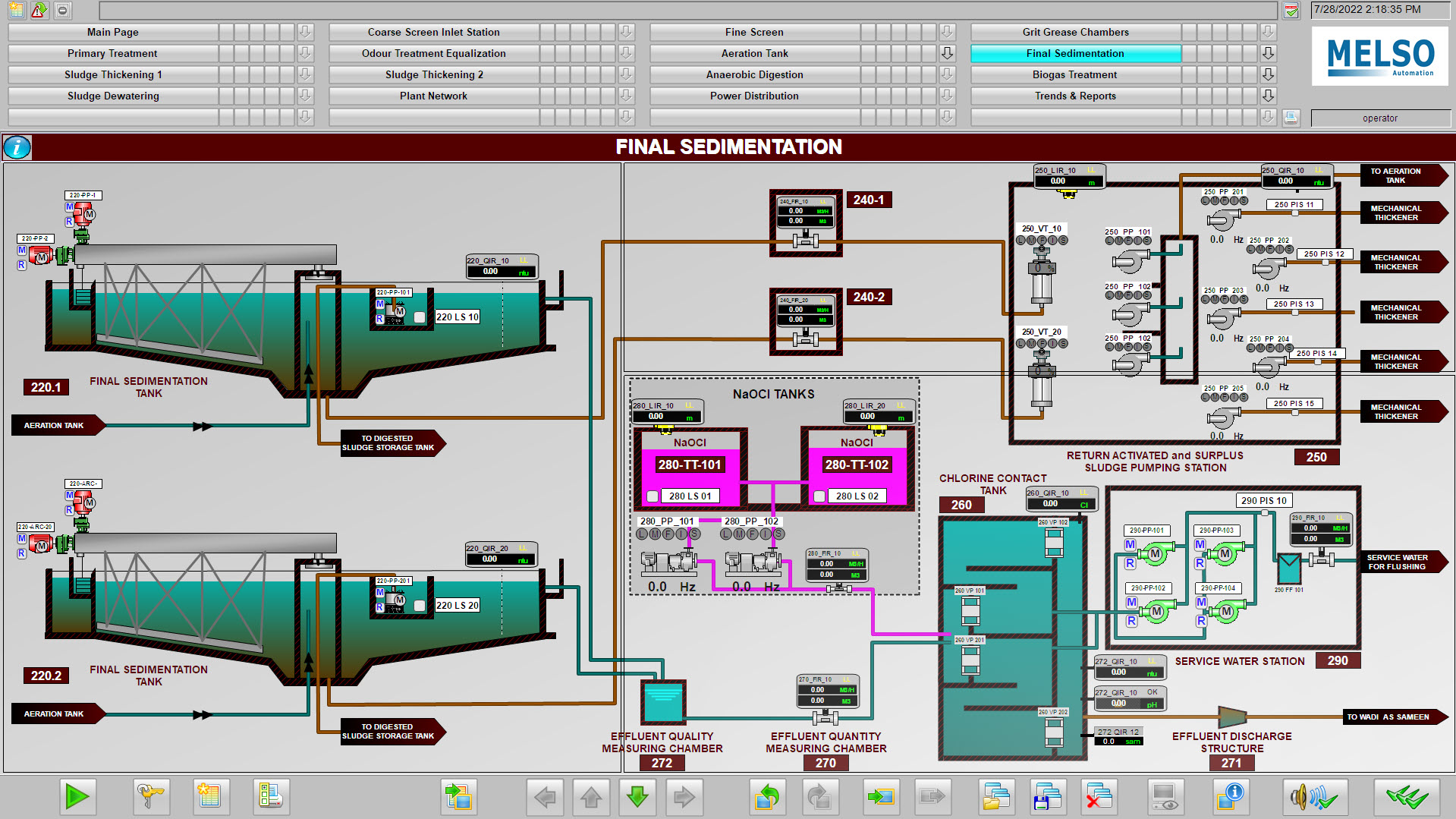

Writing PLC&SCADA Programs:

In line with the project requirements during the implementation phase; Creates FDS and writes PLC Programs in Ladder, STL, FBD, SCL and CODESYS languages

Creates SCADA Graphic Screens and writes programs. It carries out software testing and simulations of PLC & SCADA programs in Office Test and Simulation stations, and invites you to participate in the tests at this stage.

LV Panels;

In parallel with PLC and SCADA Programs, LV panels MDP-PFC-MCC-PLC-LCP Electrical Projects are prepared and the assembly of the panels is completed in our own panel production areas. It is ready for FAT Tests.

FAT (Factory Acceptance Tests):

At the end of the assembly of MDP, PFC, MCC & PLC Panels, it applies the Factory Acceptance Test (FAT) procedures, this stage invites you to the manufacturing workshop, completes the complete Electrical and PLC & SCADA Tests of the system, under the supervision of your project managers and, if necessary, under the supervision of companies such as Bureau Veritas and Türk Loydu, FAT prepares reports.

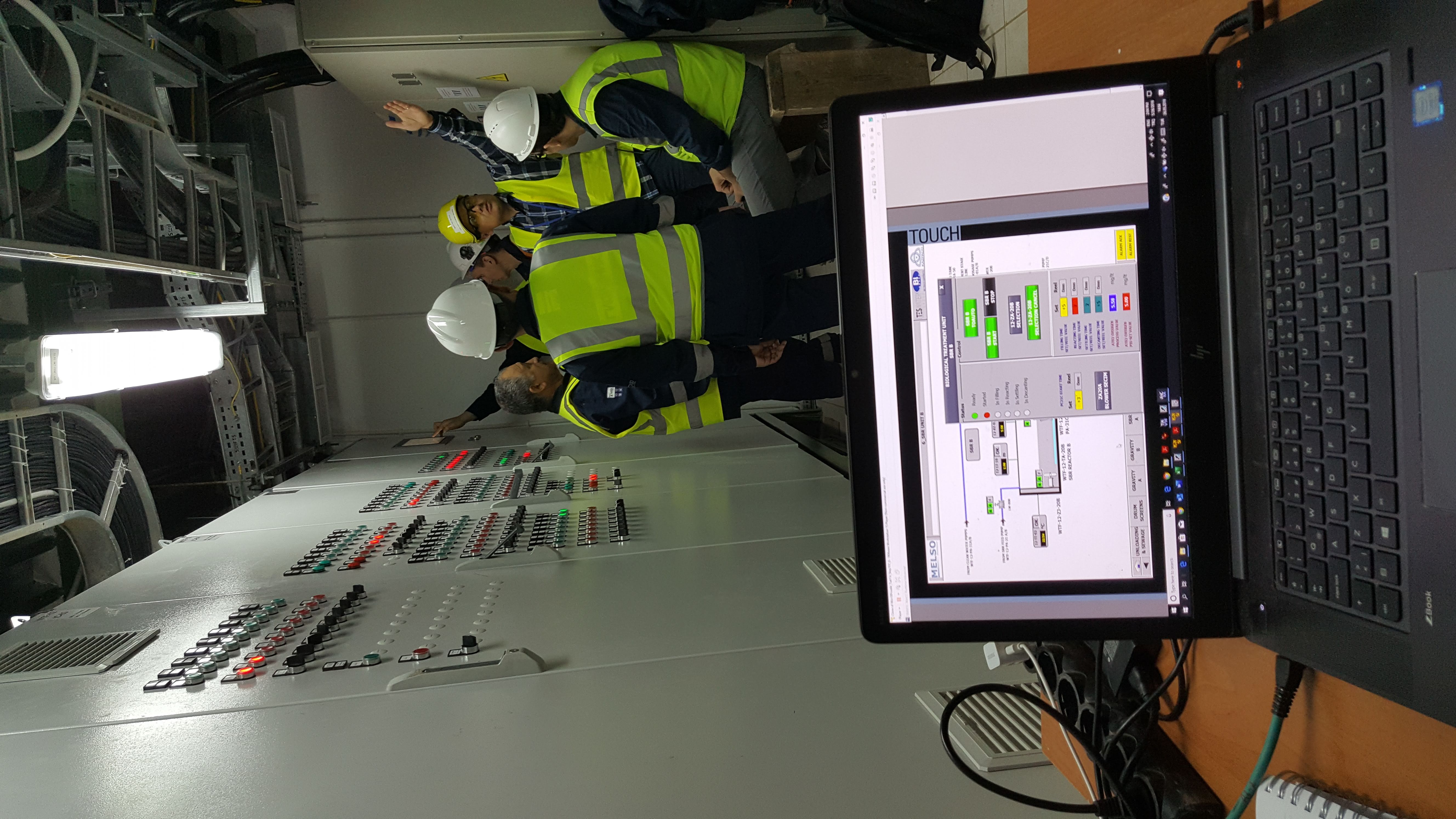

SAT (Field Acceptance Tests):

Scope of commitment: Power and Signal Cables, Cable Carrying Systems, Grounding-Lightning Rod, Lighting, Fire, Telephone, CCTV etc. It carries out the installation and installation of complete electrical works. It commissions the panel, instrument cable end connections and tests. It delivers on a turnkey basis.

It performs Field I/O, Signal tests, MDP-PFC-MCC-PLC-LCP complete LV Panels signal and electrical tests with PLC, Parameterization of Driver & SoftStarter, Instruments and Devices.

After completing SAT electrical tests, the control room SCADA computer provides complete Control and Surveillance of the Facility from Graphic Screens.

Faults occurring in the facility are displayed on the Alarm Screens, as is the Pressure, Temperature, Flow, Level, etc. of the Facility. It allows process values to be monitored in Graphic and Table formats on Trend screens, and Facility Process values and Reports on Reporting Screens.

It supports the arrangement of the Control Room and installs SCADA Computers, Monitors, Printers and UPSs. It ensures PLC & SCADA communication, passes the Field Acceptance Test (SAT), and checks the accuracy of the connections of the drawn cables to Equipment and Instruments. It also provides support for instruments, parameters and calibration in the field.

According to the training program prepared by the Commissioned Facility for the Automation Maintenance team; It provides training in Istanbul central training halls and in the field via the PLC programs, SCADA Screens and programs of the project. In this context; In case of malfunctions in the system and planned maintenance periods; It explains and shows in full detail how to intervene in the Hardware and Software of the system, on PLC Programming Computers and SCADA Computers. Provides training to Facility Operators on how to Control and Surveillance of the System via SCADA.

.png)

Prepares the SAT report after the facility is commissioned. Electrical Projects prepare As-Builts, user manuals and training documents, deliver these documents to the Maintenance team and Facility operators and withdraw them from the Facility.

Melso Automation immediately meets all your software and hardware demands that will increase the efficiency of the facility, during the initial operation phases of the commissioned facility. It provides 24/7 support and service by intervening locally and remotely for all kinds of adjustments and additions to PLC and SCADA software.

For more info about the Project and Fotos :

https://www.facebook.com/m.otomasyon/photos

www.linkedin.com/in/melso-otomasyon-a-%C5%9F-56396586/details/projects/

www.linkedin.com/in/mustafa-%C3%A7etin-55b74926/details/projects/